Unsere Fusion – Bereit für die Zukunft der Automation

Aus BEWA solutions (vormals HW Elektrotechnik) und BeWa Automatisierung wird BEWA solutions – A member of the SCHOTTEL Group. Zwei erfahrene Partner bündeln ihr Know-how zu einem innovativen Anbieter für individuelle Automatisierungslösungen – clever, effizient und zukunftsweisend.

Unsere Fusion – Bereit für die Zukunft der Automation

Aus BEWA solutions (vormals HW Elektrotechnik) und BeWa Automatisierung wird BEWA solutions – A member of the SCHOTTEL Group. Zwei erfahrene Partner bündeln ihr Know-how zu einem innovativen Anbieter für individuelle Automatisierungslösungen – clever, effizient und zukunftsweisend.

NEWS – NEWS – NEWS

Wir freuen uns, Ihnen mitteilen zu können, dass die Fusion zwischen BEWA solutions (vormals HW Elektrotechnik) und BeWa Automatisierung nun erfolgreich abgeschlossen ist. Das gemeinsame Unternehmen firmiert ab sofort unter dem Namen BEWA solutions – A member of the SCHOTTEL Group.

Unsere neue Website ist aktuell in der finalen Umsetzung. Bis dahin finden Sie alle wichtigen Informationen zu unserem fusionierten Unternehmen bereits auf unserem Onepager. Eine inhaltliche Anpassung der vorliegenden Website kann leider nicht mehr erfolgen.

Vielen Dank für Ihr Verständnis und Ihre Unterstützung während dieser Übergangszeit.

BEWA AUTOMATISIERUNG – ENTWICKLUNG, KONSTRUKTION UND FERTIGUNG VON SONDERMASCHINEN

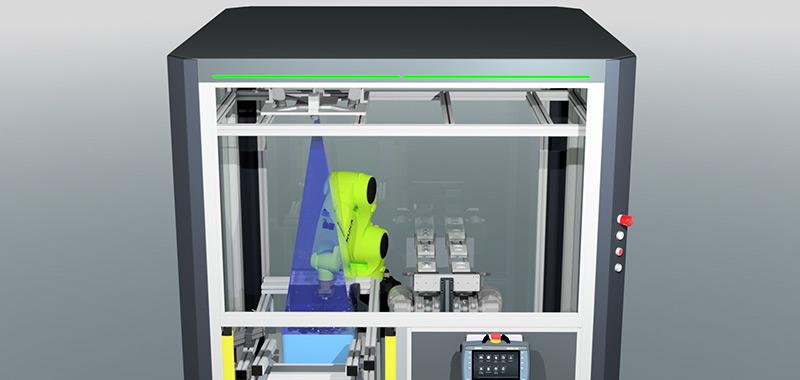

BeWa Automatisierung GmbH ist ein innovatives und mittelständiges Familienunternehmen im Bereich Sondermaschinen- und Anlagenbau sowie Automatisierungstechnik. In enger Zusammenarbeit mit unseren Kunden entstehen individuelle Lösungen für Montage-, Füge- und Prüfsysteme.

Mit Hilfe modernster Zerspanungstechnologien fertigen wir Einzelteile effizient und hochpräzise. Durch die hausinterne Montage der Baugruppen verkürzen wir Lieferzeiten und bieten maximale Flexibilität.

Dank des Tochterunternehmens BeWa Control GmbH setzen wir auch komplexe Programmierungen im Bereich SPS-, PC-, Roboter- und Kameratechnik um.